Home > Company News > The Difference of Electric Nibbler VS Shear

Company News

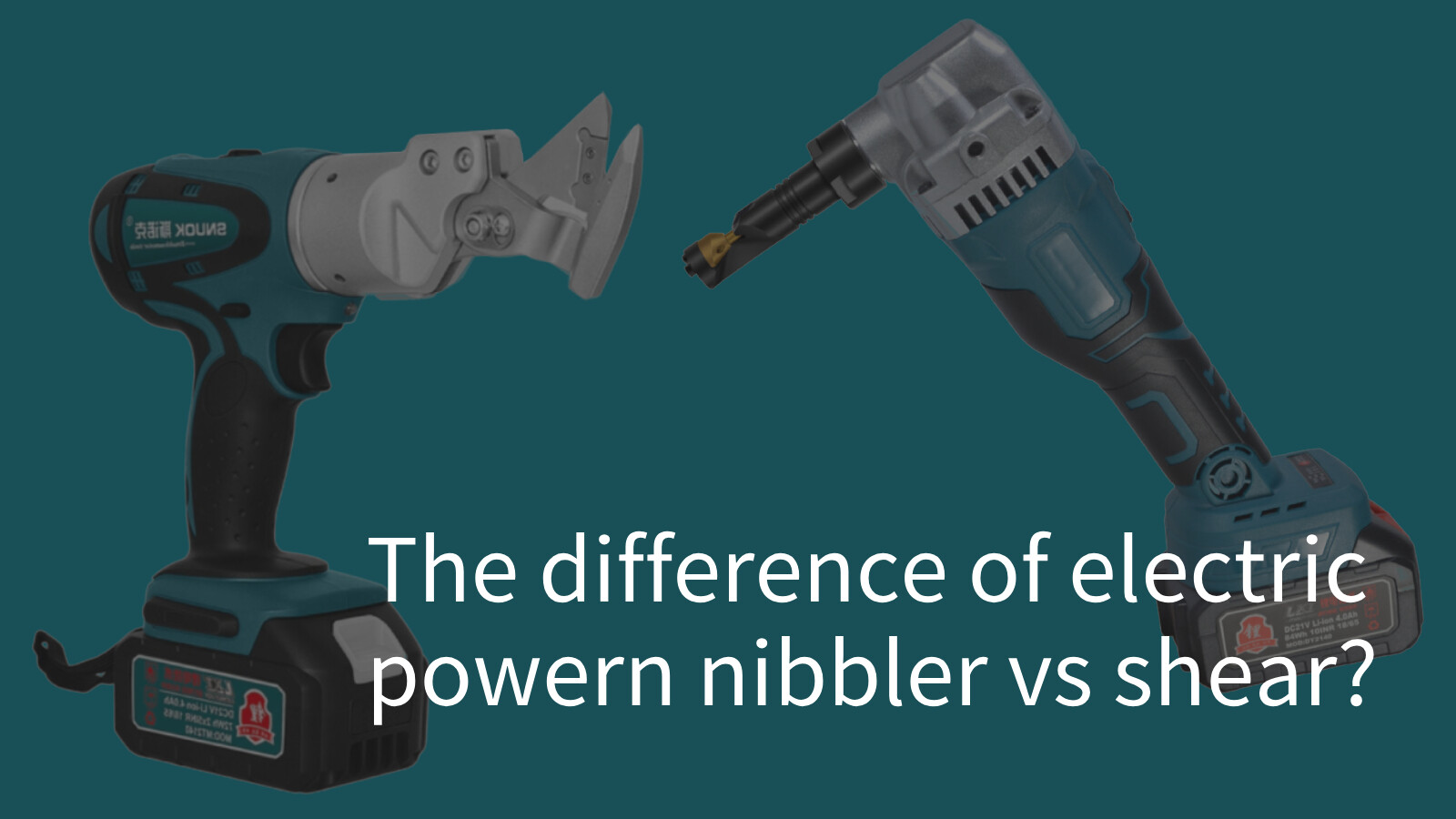

Power electric nibblers and shears are common cutting tools used in metalworking and manufacturing. Their purpose is similar, but there are some differences in design, operation, and application. Hereâs a comparison between the two:

Electric nibblers:

Operation: Electric punching shears use a punch and die mechanism to cut sheet metal. The punch moves in a linear or rotary motion and creates small notches or cuts in the material.

Cutting speed: Electric punching machines typically have relatively high cutting speeds, especially when dealing with intricate or curved cuts.

Cutting Paths: Punching shears are great for tight curves, circles, and complex shapes. They can be cut in any direction, including curved or straight.

Material Thickness: Electric punching shears are good for cutting thinner sheet metal, usually up to about 1/8 inch (3 mm) thick.

Surface Quality: The puncher produces a clean, burr-free edge, making it suitable for applications where a smooth surface is important.

Noise and Vibration: The punching and shearing machine may be noisy and generate some vibration during operation.

Shears:

Operation: The scissors use a scissor-like motion to cut sheet metal. Two sharp blades come together to cut material.

Cutting speed: Compared to punching and shearing machines, scissors generally have a slower cutting speed, especially for intricate or curved cuts.

Cutting path: Scissors are best for straight cuts. They are not as versatile as punching and shearing machines when it comes to cutting curves or complex shapes.

Material Thickness: Shears can handle thicker sheet metal than punching shears, typically up to 1/4 inch (6 mm) or more, depending on the specific shear.

Surface Quality: The scissors can produce a clean cut, but there may be some burrs or deformation of the cut edges, especially with thicker materials.

Noise and Vibration: Scissors are generally quieter and generate less vibration than punching and shearing machines.

Choose between electric punching shears and scissors:

The choice between electric punching shears and shears depends on your specific needs and the type of work you will be doing. If you need complex shapes, and curves, or need to process thinner sheets, an electric punching, and shearing machine may be more suitable. On the other hand, if you primarily need straight cuts and are working with thicker material, scissors may be a better choice.

When deciding between these two tools, it is important to consider factors such as material thickness, cut complexity, desired finish quality, and overall workflow. Always follow the manufacturerâs guidelines and safety precautions when using any cutting tool.

Popular Searches

- multi-master oscillating tool

- electric wall chaser

- electric hot knife cutter

- electric hot knife

- foam knife

- foam hot knife cutter

- eps knife

- rubber cutting hot knife

- electric rope cutter

- the renovator tool

- hot knife rope cutter

- eps foam knife

- foam cutting hot knife

- webbing hardware

- heated knife

- hot cutter knife